Does meat have high water content or is it dry, like the Sahara sky?Check out this article, it explains how moisture in meat won’t run dry.

This article is part of series. Check them out all!

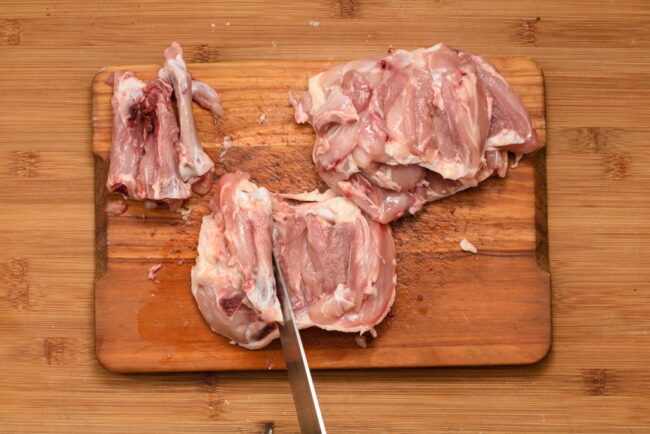

The moisture content in meat and poultry that is present naturally can be quite astonishing. These foods are comprised of various components including water, muscle, fat, connective tissue, and bone. The muscle, which is the part most commonly consumed by people, is typically around 75% water and 20% protein, with the remaining 5% consisting of carbohydrates, fat, and minerals. The amount of water in meat is dependent on various factors such as the type of muscle, the meat type, the season, and the meat’s pH level. Fat is present both between and within muscles and contributes to the flavor and juiciness of the meat.

Regarding water content, a chart shows that an eye of round roast has a 73% water content before cooking, which reduces to 65% after cooking. Similarly, a whole broiler-fryer has 66% water before cooking and 60% after cooking. Leaner meat and poultry tend to contain more protein and less fat. As water is a component of protein but not fat, leaner cuts tend to have a slightly higher water content per weight basis.

| Product Name | Percentage Water Raw | Percentage Water Cooked |

|---|---|---|

| Chicken fryer, whole | 66% | 60% |

| White meat chicken, with skin | 69% | 61% |

| Dark meat chicken, with skin | 66% | 59% |

| Ground beef, 85% lean | 64% | 60% |

| Ground beef, 73% lean | 56% | 55% |

| Beef, eye of round | 73% | 65% |

| Beef, whole brisket | 71% | 56% |

Leaner Meat Contains More Water

Consumers have been known to remark that modern-day beef contains more water and lacks the same flavor as beef in the past. This is partly due to the breeding of leaner animals, which naturally have a higher water content. Fat in meat is a significant contributor to flavor, so leaner cuts may have a different taste than fattier ones. To address this issue, some leaner cuts of meat are enhanced with a flavor solution.

Value-Added Meat and Poultry Products

nToday, many grocery stores offer meat and poultry products that have been enhanced with flavoring solutions. These solutions can be added through marinating, needle injection, soaking, or other methods. The labeling of such products must state the presence and amount of the solution, along with the ingredients. The labeling term “marinated” is only permitted for products with specific amounts of solution: 10% for marinated meats, 8% for boneless poultry, and 3% for bone-in poultry.

The solutions added to the meat or poultry for flavoring, seasoning, and tenderizing are intended to be part of the product. Therefore, they are required by regulations to be identified as part of the product name and considered part of the product, regardless of whether the solution is incorporated into the product or is free-flowing.

Natural Products

Meat and poultry that consist of one single ingredient are considered “natural.” However, some products that are labeled as natural may also contain a flavoring solution, as long as the ingredients used in the solution are minimally processed and not artificial, such as natural flavoring. There are no restrictions on the amount of solution that can be added to products with a natural claim. A brief statement explaining what “natural” means should accompany all products making this claim.

Freezing Meat and Poultry

When meat and poultry are frozen, the natural water in the meat turns to solid ice crystals that expand and push into the surrounding tissue, rupturing cells. The water outside the cell membrane freezes first, which leeches water from inside the cell membranes. When the product is thawed, the original balance does not return to normal, and it loses some of its natural springiness. The thawed product will have less water, and the released water seeps out of the thawing meat and poultry into the package.

The smaller the ice crystals are, the less damage they do. Products that are flash-frozen by the manufacturer have superior quality to fresh products frozen by the consumer.

Moisture Loss from Meat and Poultry

Meat and poultry are transported from slaughter and processing plants in refrigerated trucks that can be kept as cold as 1°F. Although they may not be frozen solid, they are in a semi-frozen or “hard-chilled” state, so any moisture in the product is held in the tissue of the product.

Beef is often ground while partially frozen, so there may appear to be more liquid in it because of the ice crystals.

When products are displayed in refrigerator cases at 26°F, the cells of the product loosen up, and some of the moisture melts and gradually seeps out. This production of visible meat or poultry juice is known as weep or purge and occurs during display of retail cuts, shipment of wholesale cuts, and storage of cuts prior to shipment.

In a home refrigerator set at 40°F or below, even more liquid will seep out of the product. The longer a product sits in the refrigerator, the more liquid will be released from the muscle cells.

Meat and poultry products are packaged in different ways to preserve their quality and extend their shelf life. Vacuum packaging is a common method that involves air- and leak-proof packaging under vacuum. Some packages also contain specific gases to preserve flavor and quality. While these packages are effective at prolonging storage times, they can extract the juices out of the meat and accumulate them in the package. In contrast, plastic-wrapped packaging used in most supermarkets allows for some evaporation.

The USDA’s Food Safety and Inspection Service (FSIS) has regulations and policies that require labeling of meat and poultry products that have retained or absorbed water from post-evisceration processing. This process involves chilling recently slaughtered animal carcasses and their organ meats to a safe temperature. If the product has absorbed water during this process, the label must include a statement with the percentage of retained or absorbed water.

Raw poultry products absorb some water during cooling in a chill-tank, which must also be declared on the label. Beef carcasses are rinsed during slaughter, but the small amount of water used is usually absorbed on the surface of the meat and quickly evaporates or drips out. Beef carcasses cooled with water during post-evisceration processing must be appropriately labeled with the retained water statement.

When cooking meat and poultry, the higher the cooking temperature, the more moisture will be lost. Beef roasts can lose up to 1/3 of their original size and weight when cooked at high temperatures or for too long.